Our experience at your service.

We always aim at keeping up with the new technologies available on the market so that we can continue to offer a product with cutting edge technology. That is why we are always ready to tackle a market where technology keeps evolving and this commitment is expressed in the ongoing training and refresher training of our staff and also in the use of modern tools and the very latest computer solutions.

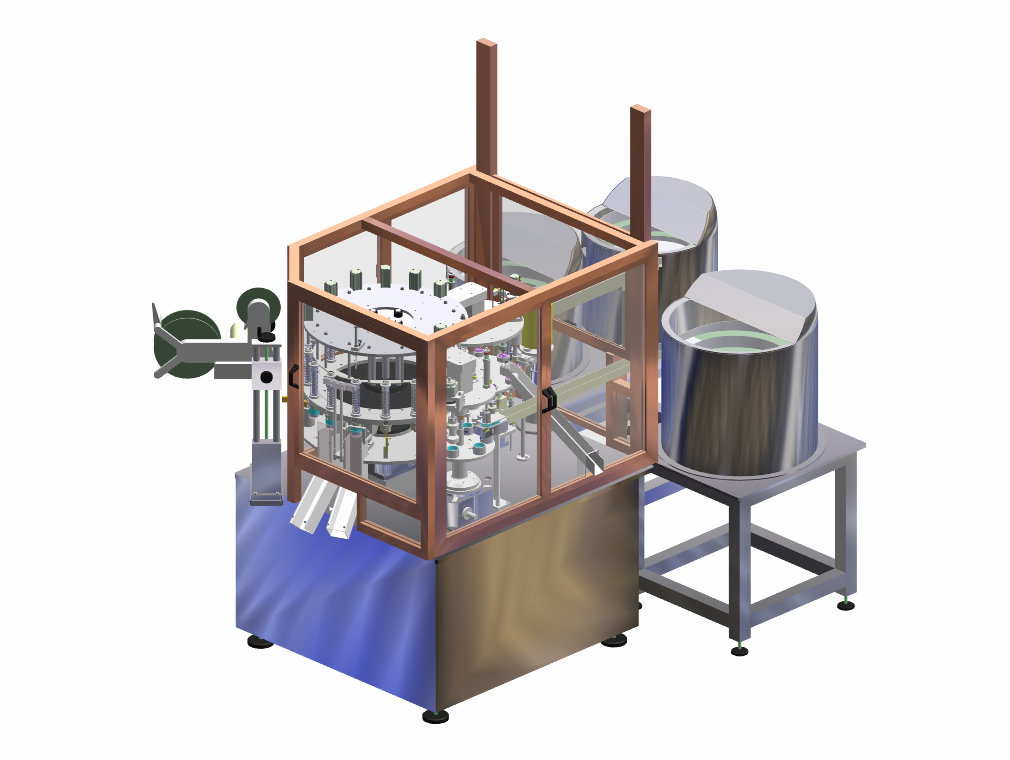

Some years ago the firm introduced three-dimensional design, enabling virtual simulation of all the automation movements and of forming before they are built, which allows use to create increasingly complex and intricate systems.

Some years ago the firm introduced three-dimensional design, enabling virtual simulation of all the automation movements and of forming before they are built, which allows use to create increasingly complex and intricate systems.

All our products are designed using the latest version of CAD 3D software, updated twice a year.

The production department uses vertical work centres and control lathes and grinding machines, which are programmed using CAM 3D technology.

We also have electron discharge machines (EDM) for the precision cutting and mould sinking of hard metals.

The software of our automated systems is developed entirely by highly qualified experts and this enables us to make quick and totally custom engineered changes.

Moulds are tested by measuring a sample of the parts formed, using a dimensional control machine. We can also use the same machine for reverse engineering.

An internal data network enables us to reduce the time taken for passing information between the design stations and the work stations without the need to produce drawings on paper.

The times and costs of each job are monitored by a software system that facilitates supervision and control.